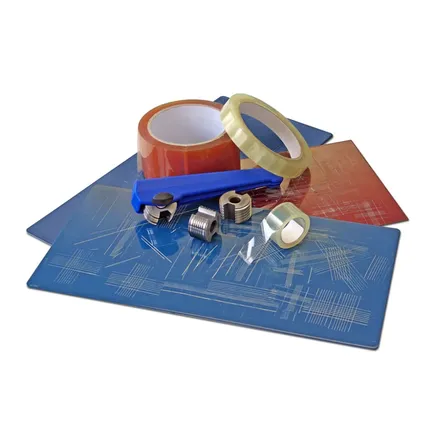

The cross-cut test (as per DIN EN ISO 2409) has been the most globally established method for determining coating adhesion for many years. Using a specified cutting tool /1/, a defined grid pattern of 2 x 6 intersecting cuts is made, penetrating the coating to the substrate or exposing the substrate along the entire length of the cuts. Depending on the properties of the coating being tested, the results can range from an intact grid to frayed edges or detachment at corners and edges, or even partial or complete delamination across the 25 squares of the grid.

The result is evaluated visually against reference images from a table and expressed as a numeric value, providing a communicable framework that has stood the test of time.

The use of adhesive tape in cross hatch cutting has been ubiquitous for years. However, its contribution to test results can be speculative or misleading unless there is a clear agreement among all parties involved. Questioning the methodology is not only reasonable but overdue, given the varied perspectives, convictions, and experiences surrounding it. This lack of consensus does little to promote the goal of standardizing or precisely defining testing methods.

Inquiries from concerned users

The motivation for this article stems from frequent user inquiries – nearly weekly – seeking guidance on standardized adhesive tapes, clarification of the current situation, or recommendations for proper procedures. For users, quality assurance has significant financial implications: reliable verification of product quality and protection against unwarranted complaints through standardized testing.

Common sources of errors and misunderstandings

This article aims to highlight some fundamental issues that may improve test reliability and accuracy for users, rather than citing exhaustive data.

Previously, DIN EN ISO 2409 specified the use of a 10-N adhesive tape (25 mm width, ±1 N tolerance) for "cross-cut tests on hard substrates" to remove loosely adhering coating material before assigning a score.

However, could the tape's high adhesion potentially introduce additional strain on the sample, affecting results? Many users mistakenly equate the use of a defined adhesive tape with a precisely defined additional peeling force. Yet, the inherently variable factors affecting the tape’s peel strength, including user application, undermine such assumptions.

The peel-off value of adhesive tape

The adhesive removal value of the tape is usually verified by the manufacturer. This is done by applying the tape, using a specific rubber-coated roller, onto a defined smooth and clean steel surface with a controlled pressure. The tape is then peeled off at a constant speed and angle of 90°.

The adhesive bond strength, however, can vary significantly depending on the type of coating surface (e.g., high-gloss, semi-gloss, or matte finishes) being tested. Moreover, the manual application of the tape, described in DIN EN ISO 2409 as "rubbing the tape firmly with a fingertip or fingernail," introduces variability. The extent of pressure applied and even frictional heat could influence the adhesive strength, leading to inconsistent results across different users.

The extension of the acceptable adhesive strength range to 6–10 N has not fundamentally resolved or improved the situation. Instead, it was intended to ease the procurement of suitable adhesive tape without limiting users to specific suppliers.

Considering the inherent variability in user-dependent application methods, the strict adherence to adhesive tape specifications may ultimately be negligible. This should be evaluated and ratified by the standards committee during ongoing revisions or improvements.

The latest draft of DIN EN ISO 2409, still pending final approval at the time of this article’s publication, aligns better with real-world conditions. It makes the use of adhesive tape optional, depending on agreements among all parties involved in the testing process. Key factors for consensus might include:

- Manufacturer or supplier of the tape

- Source and type of adhesive tape

- Batch number

- Storage conditions

- Application method onto the coating material

- Peeling time, angle, and speed

- Climatic conditions during testing

As was credibly presented to the author and by a tape manufacturer, the creation of a tape with a reliably defined and tightly controlled adhesive peeling force beyond the limitations described below is seen as idealistic wishful thinking:

The manufacture of tapes does not take place in the form of small, user-friendly rolls that are familiar to consumers, but rather on much larger coils. Here, for example, production-dependent temperature zones can arise (e.g., core zone, middle zone, and outer zone, with transitions being naturally understood as flowing), which may require different times for cooling to room temperature. The influence of temperature or its duration can affect the properties of the adhesive and thus also impact the adhesive peeling force.

The creation of small tape rolls for the end consumer takes the form of unwinding, cutting, and then rewinding onto small rolls, with within a batch (the production volume of a coil) not necessarily being divided and distinguished according to temperature zones or possible effects on the adhesive peeling force. The adhesive peeling force is typically checked through a representative cross-section of a predetermined number of samples. It would be economically unimaginable to test each roll individually for its properties.

Additionally, adhesive tapes in general are not indefinitely storage-stable, and the nature and speed of changes are naturally influenced by storage conditions. Moreover, the end user, who with his expertise and technical equipment would be able to periodically check his tape for reliable data, is more the exception than the rule. However, even then, it would not really make sense given the differences in adhesive affinity to different substrates as described above regarding supporting or ensuring test accuracy and repeatability.

Conclusion

The suitability of adhesive tapes as a testing medium is individually critical depending on the expectations and experiences of the respective users, as well as their willingness to accept potential inaccuracies when expressing test results in numerical values. Where the use of adhesive tapes as a testing medium has already been verified as effective, there is no compelling reason to have to universally forgo their use in the future. However, users who have already identified clear inconsistencies in their use, as well as potential new users, should weigh all the pros and cons related to their testing context before burdening their quality testing with a potentially dubious testing issue or adding it unnecessarily.

Much in the use of adhesive tapes seems indeed influenced by tradition mixed with an individual understanding of standard requirements and personal taste. In fact, there are currently no universally reliable findings available about whether and when the use of adhesive tapes definitively makes sense.

Given the variety of possible configurations around the testing topic of cross-cut, it is difficult to imagine that a user can simply take a decision on whether to forgo or use adhesive tapes and select a testing medium without thorough consideration. It remains necessary to inform and educate about the lived reality, the facts, the possibilities, and, as a truly helpful factor, the agreement of all parties involved in each case.

Literature

/1/ According to DIN EN ISO 2409, two non-comparable versions of cutting tools are permitted.

Equipamento de teste ERICHSEN

A força adesiva de um material de revestimento é de importância crucial para manter as propriedades desejadas, que podem normalmente ser resumidas nas funções principais de proteção e decoração. Por vezes, estas funções são importantes separadamente, mas muitas vezes são-no em conjunto. Um teste amplamente utilizado para a força de adesão é o corte transversal, que pode ser efectuado manualmente (modelo série 295) ou automaticamente (modelo série 430 P-Smart).

Mais informaçõesAuthor

Günter Kalinna,

Product Manager Surface Technology,

Erichsen GmbH & Co. KG