K HAND COATER 620

Videos

By clicking on the following button, you agree that videos may be loaded from YouTube. You can find information on this in our privacy policy.

Link

Description

The K Hand Coater also enables very reliable colour comparisons between two or more products, since the films can be applied simultaneously side by side. The products remain clearly separated and do not flow into each other. In many sectors, there is a need for a simple way to apply coatings. In the case of printing inks, lacquers, adhesives, etc., the physical characteristics (such as colour tone, gloss, opacity and elasticity) can be assessed by applying a defined coating thickness to different substrates. In these cases, the K Hand Coater is a suitable device that can be used both within the R&D laboratory and in production for checking the manufacturing quality.

Suitable substrates include paper, fibreboard, cellulose and other plastic films, metal foils and plates, glass plates, wood, textiles, leather, linoleum and many more. All types of paints and varnishes, liquid and viscous printing inks, adhesives and fillers, emulsions, nail varnishes, wood stains, hot-melt adhesives and waxes (with appropriate temperature pre-treatment of the K-bars) can be applied.

The K Hand Coater also allows very reliable colour comparisons between two or more products, as the film application can be done simultaneously side by side. The products remain sharply separated and do not flow into each other.

Design

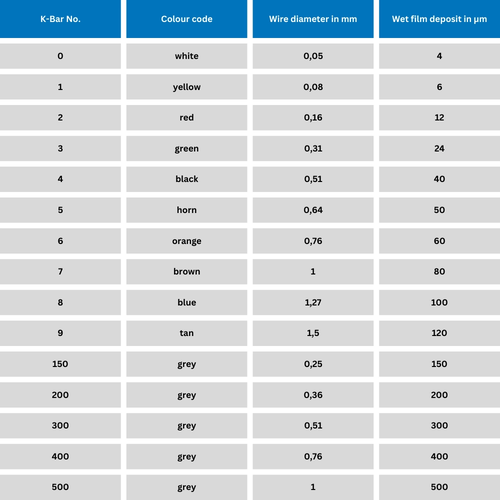

The K-rods consist of a steel core wrapped with special stainless steel wire. The cross-sections of the different wires are dimensioned in such a way that exact wet films between 4 μm and 500 μm can be drawn on. The K-rods are identified by numbering and different colours of the handles. The short rods can be used for mounting widths of approx. 11 cm.

The following table summarises the numbers, colour coding and wet film thicknesses of the inpidual K-bars:

The impression bed has a surface made of synthetic rubber (with a fixed hardness) and is provided with a clamp for fixing the substrate. Corresponding to the length of the long K-bars, the impression beds are also designed in the width 11 x 22 cm.

Handling

The substrate to be coated is fixed to the impression bed with the clamp and the substance to be applied is applied with a small distance in front of the clamp. The selected K-rod is grasped with both hands and, starting above the substance - without rolling, is pulled at a steady speed to the bottom of the impression bed. After each application, the K-bars should be cleaned with a lint-free cloth and placed in the solvent container.

Scope of delivery

- 4 short standard squeegee bars (no. 0, 1, 2 and 3) or your choice of 4 short standard squeegee bars (please specify)

- Small Impression bed (coating area: 11 x 18 cm)

- 500 sheets proofing paper 12 x 21 cm (matt/glossy)

- Short cleaning/storage rack