A layer that is too thin gives insufficient protection and low covering power. Therefore, minimum coating thicknesses are required in technical delivery conditions and their compliance and uniformity must be constantly monitored.

On the other hand, a layer that is too thick means corresponding additional consumption of coating material and thus an unnecessary increase in costs. In addition, thicker layers do not always have better properties, e.g. in terms of drying time.

Physical and mechanical properties of coatings are directly dependent on the coating thickness. Therefore, if one wants to test comparably and reproducibly, this must be done with the same coating thicknesses.

Advantages of mechanical coating thickness gauges

- Very handy, easily transportable and simple to operate, even by assistants

- Robust construction, direct reading

- Purely mechanical measuring principle

- Measurements are possible on any surface, whether glass, wood, metal or plastic

- Mechanical coating thickness gauges are very inexpensive compared to other systems

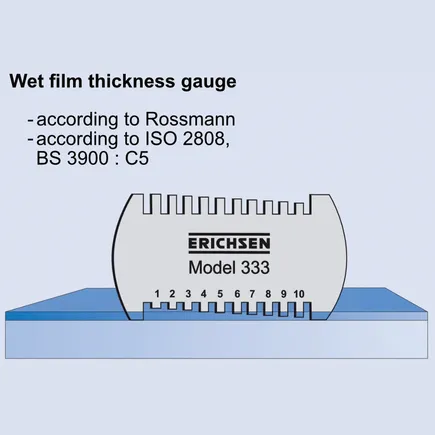

Wet film thickness gauges

Test method

Wet film thickness gauges are used to check freshly applied coatings and allow the calculation of the remaining dry film thickness. If deviations from the nominal value are detected, corrections can be made immediately.

- Model 333 & 433 – According to Rossmann, ISO 2808 and BS 3900:C5

- Model 234 – According to ISO 2808, ASTM D 1212, BS 3900 : C5

Our ERICHSEN Wet Film Thickness Gauges

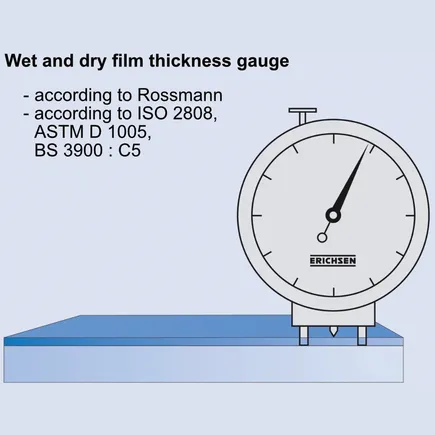

Dry film thickness gauges

Test method

Dry film thickness gauges are used to check finished coatings.

ERICHSEN Testing Equipment

ERICHSEN is involved, among other things, with demand-oriented testing of high-quality surfaces. As a partner to users and research, and through long-standing collaboration with standard-relevant committees, we have established a range of test instruments over the years with which quality-related properties of many products can be determined precisely and conveniently.

More information