Test method

Deep drawing (stretch forming) is the name given to the deformation process of a sheet metal under biaxial stress. The sheet is deformed with a rigid tool.

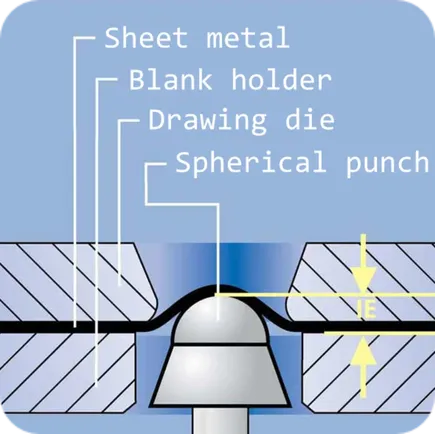

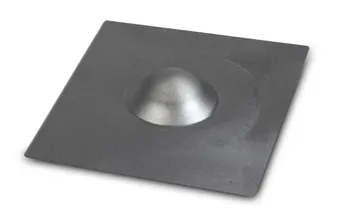

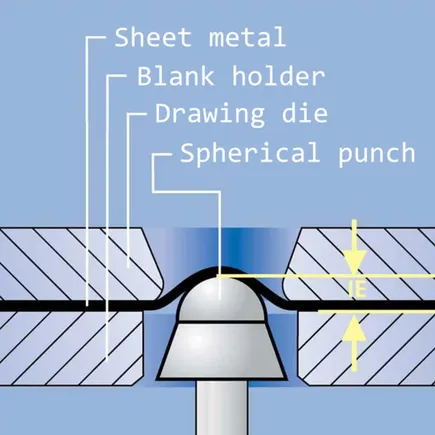

The sheet to be tested is clamped between the sheet holder and the die and formed with a hardened ball punch. This process is continued at a specified speed until a fine, continuous crack appears in the sheet. The distance travelled by the ball punch to the crack is referred to as the indentation value "IE" (in mm) and represents an important quality feature of the tested sheet metal.

Test principle of the Erichsen cupping test

ERICHSEN Testing Equipment

ERICHSEN Sheet Metal Testing Machines are suitable for a large number of forming tests (Erichsen cupping tests, Deep drawing tests, Bulge tests, FLC tests, etc.).

More information