Test method

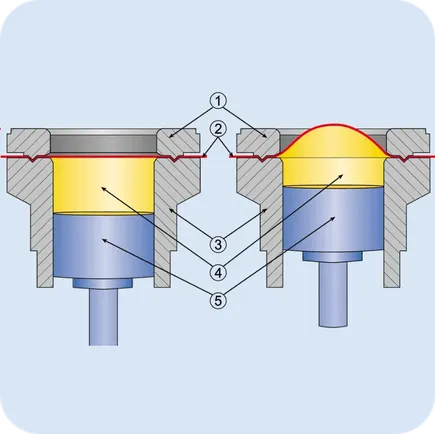

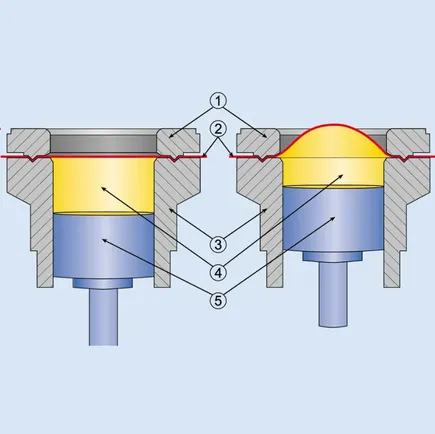

The sheet specimen (2) is fixed between the drawing die (1) and the sheet holder (3). There is an oil chamber (4) under the specimen. The sheet is clamped and can now be formed (without friction) with the help of the drawing piston (5), which presses upwards against the oil.

Test principle of the bulge test according to ISO 16808

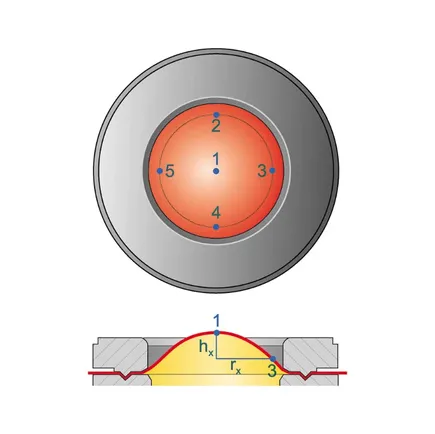

Parameters

Only five selected reference points on the sheet are relevant for determining the parameters (see top view and side view on the left), which are used to calculate the crest radius and the crest height.

ERICHSEN Testing Equipment

ERICHSEN Sheet Metal Testing Machines are suitable for a large number of forming tests (Erichsen cupping tests, Deep drawing tests, Bulge tests, FLC tests, etc.).

More information