TABER® ABRASER 352

Videos

By clicking on the following button, you agree that videos may be loaded from YouTube. You can find information on this in our privacy policy.

Link

Description

The TABER® ABRASER 352 S (Platform), with its attractive and modern design, is a robust tabletop unit. The precise control and drive elements are located in a sturdy aluminium housing. Easy operation is via LCD touch screen, with functions such as abraser status, visual reference of completed test, cycle/time switching (completed or remaining), programmable pause interval, language selection and much more. The TABER® ABRASER Model 352 S (Type 1700) has one specimen holder for performing abrasion tests.

Purpose and application

Resistance to abrasion is one of the most important mechanical properties of surfaces. Among the methods used to test abrasion resistance, working with the TABER® ABRASER is the most common and widely used method. Numerous national and international standards make explicit reference to this test instrument. The Original TABER® ABRASER can be used to perform abrasion tests on paintwork and other coatings, such as rubber, paper, leather, ceramics, textile fabrics and metals. This device is used in research and development as well as in production and quality control.

Principle of the test

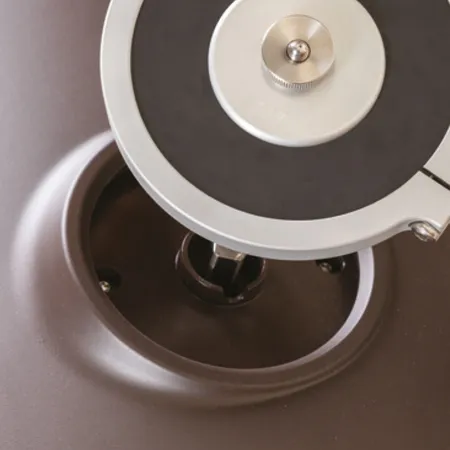

The abrasion is caused by two friction rollers which act with a defined force on the rotating specimen holder to which the specimen is attached. An essential feature of these abrasion tests is the X-shaped grid.

The abrasion behaviour can be determined by the following test methods:

Weight loss method

The material to be tested is exposed to a specified number of rotations. The abraded portion of the sample is determined by differential weighing.

Visual final test method

The sample is exposed to abrasion until the sample surface becomes visible. The number of rotation cycles is the indicator of wear.

Abrasion depth determination

After a specified number of cycles, the abrasion depth is measured with a micrometer.

Scope of delivery

- Taber ABRASER 352 S (Type 1700)

- Attachable weights (1000 g load) - 2 pcs

- Attachable weights (500 g load) - 2 pcs

- Specimen holder (pre-assembled) - 1 pc.

- Coupling ring for sample holder - 1 pc

- Torx T25 screwdriver for tightening the

Cap rings - 1 pc. - Brush for cleaning samples - 1 pc.

- Vacuum cleaner with suction brush and hose - 1 pc.

- Power cable 115/230 VAC

- Operating instructions

Standards

Technical data

Accessories

TABER® Grit Feeder 355 (980355)

Quiet Cabinet, complete set

Quiet Cabinet Top (large construction) for expansion

Quiet Cabinet, complete set (with large top)

Wheel Refacer, Model 350

Single Point Diamond Tool (120947)

Multiple Point Diamond Tool (125608)

Rotary Abraser Calibration Verification Kit

Delivery time 3-4 weeks

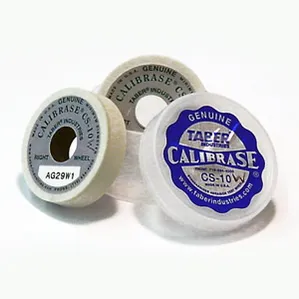

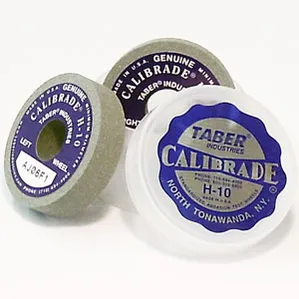

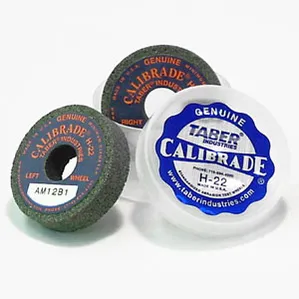

CALIBRASE-wheels CS-10, per pair

Only small quantities left in stock

CALIBRASE-wheels CS-10F, per pair

Only small quantities left in stock

CALIBRASE wheels CS-10P

CALIBRASE-wheels CS-17, per pair

Only small quantities left in stock

Testing disc ST-11 „Refacing Stone - Fine“

Felt wheels CS-5

Felt strips

Tungsten CARBIDE wheels S-35, per pair

Aluminium Wheel Set S-24, per pair

Rubber pads S-19

Specimen mounting cards S-36

Specimen mounting cards S-36-1

Specimen mounting sheets S-37

Specimen mounting sheets S-37-1

Specimen plates S-16, material: steel

Specimen Plates (birch plywood) S-17

Specimen plates of Aluminium S-18

NEMA glass standardization plates S-31

Standardization plates S-34, material: zinc, per 5 pcs

Only small quantities left in stock

Extension nut S-21

Clamp plate S-23

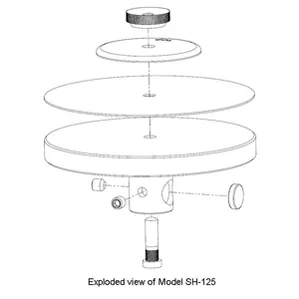

Specimen holder 'Standard' SH-125

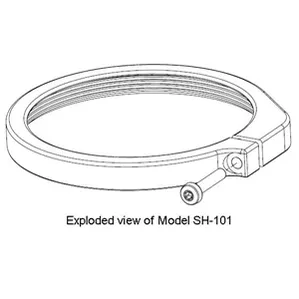

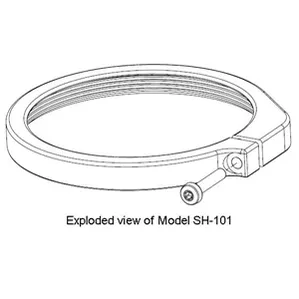

Specimen hold-down ring 'A' SH-101

Specimen hold-down ring 'B' SH-102

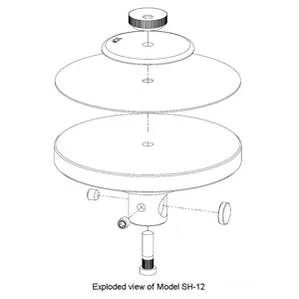

Specimen holder (tall) SH-12

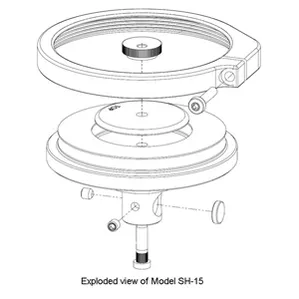

Specimen holder 'Textile' SH-15

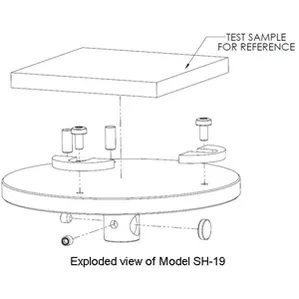

Specimen holder 'Drive Pin' SH-19

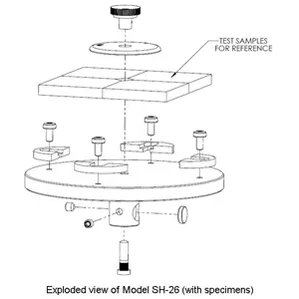

Specimen 'Sliding Mount' SH-26

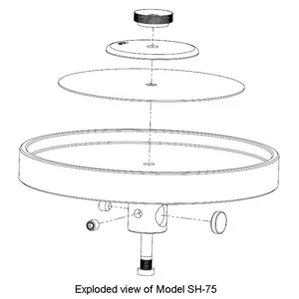

Specimen holder SH-75 - rimmed

Arm Height Extension Kit (1700-04)

Wheel tracking cards S-45/2 (132150-2)

Counterweight Set 50 g 'Arm Kit' (135369)

Counterweight-Set 125 g (135937)

Counterweight-Set 150 g (135927)

Counterweight-Set 175 g (135928)

Brush S-12

Sample cutter '5000'

'Scuffing Head' Attachment SH-300 (135647)

Scuffing Head, type 'A' (135636)

Scuffing Head, type 'B' (135637)

Scuffing Head, type 'C' (135638)

Auxiliary weight (453 g /1 lb) for 'Scuff'-Attachment SH-300

Auxiliary weight (907 g /2 lb) for 'Scuff'-Attachment SH-300

Sandpaper strips S-33, per 100 pcs

Only small quantities left in stock

Sandpaper strips S-33, per 500 pcs

Only small quantities left in stock

Sandpaper strips S-42, per 100 pcs

Only small quantities left in stock

Sandpaper strips S-42, per 500 pcs

Only small quantities left in stock

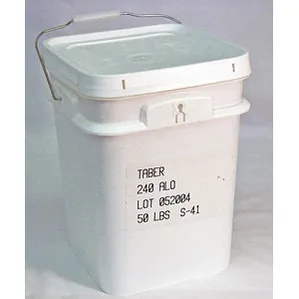

Aluminium-Oxyd-Grit S-41, 50 pound container (1 pound = 453,6 g)

Vacuum cleaner ELSEA (115 V, 60 Hz)

Vacuum cleaner ELSEA (230 V, 50 Hz)

Paper Filter Bag ELSEA (FI003C/10)