SCRATCH HARDNESS TESTER 413

Videos

By clicking on the following button, you agree that videos may be loaded from YouTube. You can find information on this in our privacy policy.

Link

Description

All methods that can be used with the SCRATCH HARDNESS TESTER 413 are basically based on the same method: The sample is mounted on a rotating table (number of revolutions in the standard version: 5 min-1). The test tool is attached to a load arm with adjustable weight that allows the tool pressure to be adjusted to the sample (load range of 0 – 10 N in 0.1 N increments and load range of 0 – 1 N in 0.01 N increments). The resistance of the sample to this effect is assessed visually using the scratch track (refer to the operating instructions for details).

Reference Class

The SCRATCH HARDNESS TESTER 413 is supplied with a Manufacturer’s Certificate M in accordance with DIN 55 350-18 that includes among others the following information: Actual and setting values of rotational speed and test load, product identification, test equipments used with calibration status, date, name of inspector. For both load ranges (1 N/10 N) the test load is compared with the specific setting value in 10 graduations.

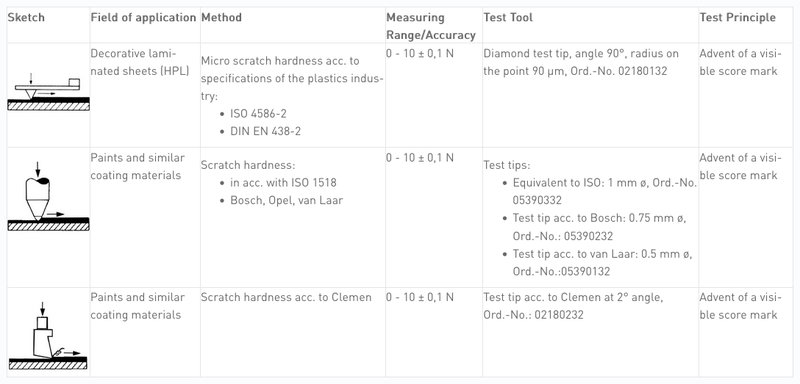

In the following table the essential test parameters are indicated:

Scope of delivery

- SCRATCH HARDNESS TESTER 413 – Basic instrument

- Load arm for fixing the test tool

- 2 weights for the load ranges 1 N and 10 N

- 1 counter weight with spirit level

- Box level

- Magnifying glass

- Screw driver

- Carrying case

- Instructions manual