Gloss Measuring System GLOSSMASTER ONLINE 507

Description

Now, more than ever, it is very important to achieve a consistent surface quality during the production and processing of surface-treated materials (such as papers, plastics, metal or wood surfaces). A uniform and defined surface quality must be ensured in almost all industrial segments. Variations in glossiness can result from manufacturing defects, supplier changes and material fluctuations. Often, these lead to complaints in quality control or even rejection of the material. Especially in recent years due to increasing demands of customers, it is particularly important to be able to make a flawless, objective assessment of the gloss.

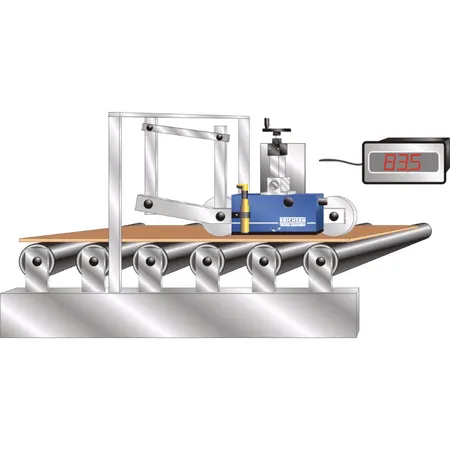

Application example – In a factory for laminated parquet

Equipment

- GLOSSMASTER ONLINE 507-60° (basic version), comprising:

- 60° Measuring head, measuring distance 10 mm, incl. sensor for scanning the test surface

- Mounting adapter

- Supply and display unit with HMI touch panel

- Reference input for min./max. gloss values and average value display

- Alarm lamp signals if the limit values are exceeded

- Time lag of 0 - 3 s to prevent minor deviations from actuating the signal

Application

The measuring head of the GLOSSMASTER 507-60° ONLINE is installed in the production line directly after the UV drying unit. The gloss measurement controls the quantity of coating applied. If the gloss value is exceeded an external alarm is activated. ONLINE gloss measurement is the final step prior to packing and palletizing.

Advantages of the equipment

- Without ONLINE gloss measurement, inpidual samples must be taken from the production line and measured and evaluated using a laboratory gloss testing device.

- Savings due to avoidance of faulty batches and the resulting coating and material costs. Potential reworking costs are also avoided.

Application example – In a galvanizing shop

Equipment

- GLOSSMASTER ONLINE 507-60° (basic version) comprising:

- 60° Measuring head, measuring distance 10 mm incl. sensor for scanning the test surface

- Supply and display unit with HMI touch panel

- Distance piece for maintaining the measuring distance

- Analogue output

Application

The galvanizing plant produces sheet zinc which is used, e.g., as material for gutters. During the manufacturing sequence the material runs through a pickling plant. The GLOSSMASTER measurement provides information about the outcome of the pickling process, making it possible to determine and adjust the pickling time accordingly. An ONLINE colour measurement is also conducted during the same manufacturing sequence. Based on the components of the colour measurement the composition and concentration of the pickling bath can be monitored and regulated.

Advantages of the equipment

- The pickling process is regulated on the basis of the gloss and standard colour values.

- Without ONLINE gloss measurements controls must be conducted by way of extensive and costly single measurements.

- Saves large quantities of material and/or high reworking costs resulting from faulty batches.

- Avoidance of scrap as a result of timely identification of errors.

Special features of ONLINE gloss measurements

- Non-contact, continuous gloss measurements during production, coating or refining operations for in-process or quality controls

- Automatic calibration as an optional feature

- Alarm signal when the prescribed min./max. tolerances are exceeded

- Choice of possible gloss measurement geometries: 20° or 60°

Scope of delivery

- GLOSSMASTER ONLINE 507-60° (basic version)

- LED with 5000 K

- Supply and display unit with HMI touch panel