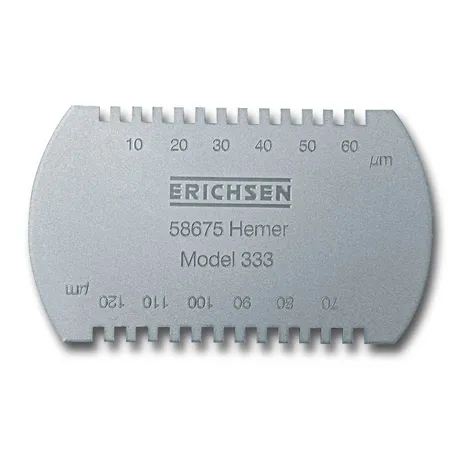

Wet Film Thickness Gauge Model 333

Shipping possible within three working days

Description

Film thickness measurement plays an essential part in the use and testing of paints and coating materials. The film thickness is a decisive factor in determining appearance, protective qualities and durability.

A film which is too thin will afford inadequate protection and reduced hiding power. For this reason, technical specifications stipulate minimum film thicknesses and regular controls must be carried out to ensure that these values are consistent.

On the other hand, an excessively thick film is the result of using too much coating material, causing costs to increase accordingly. Furthermore, thicker coatings do not always mean an improvement in properties: for example, they have an adverse affect on drying time.

The physical and mechanical properties of a coating are directly dependent on the film thickness. If meaningful testing is to be conducted, the film thickness must therefore be uniform.

Wet film thickness gauges are used to check freshly applied coatings and can also be used to calculate the resulting dry film thickness. If deviations from the specified value are detected, corrective measures can be taken immediately.

Mechanical film thickness gauges provide a number of advantages:

- Handy, portable, and simple to operate, even by unskilled personnel.

- Sturdy construction, direct reading.

- Measurements can be carried out on any surface. Since the system functions completely mechanically, substrates of glass, wood, metal or plastic are permissible.

- In comparison to other systems, mechanical film thickness gauges are favourably priced

Application

On all flat and slightly curved surfaces, as long as the measuring instrument can be applied parallel to the axis of curvature.

Test Principle

The equally long teeth 1 and 12 of the comb-shaped measuring instrument penetrate the wet film to the substrate. Between these two end positions teeth 2 to 11 are formed at a progressively increasing distance from the substrate. Teeth 6 to 11 dip into the coating whilst teeth 2 to 5 do not touch the material. The measuring result is the mean value between tooth 5 and tooth 6.

Designs and Function

The teeth on two sides of a rectangular measuring instrument made of polished stainless steel plate are cut to achieve a progressively decreasing distance from the substrate. Engraved figures indicate the distance in μm from the base material.

Available in three different ranges. The instrument is supplied in a synthetic leather pocket.

Measuring Procedure

The measuring blade with the assumed range of wet film thickness is placed on the test surface and held perpendicular. Applying slight pressure, a short "combing" movement is effected. The instrument is then lifted off vertically.

The wet film thickness is shown on the scale where the first tooth shows traces of coating material.

Scope of delivery

- Wet Film Thickness Gauge according to Rossmann, Model 333/I

- Measuring range: 0 - 120 μm (5 μm scale pision)