Cross Hatch Cutting Test

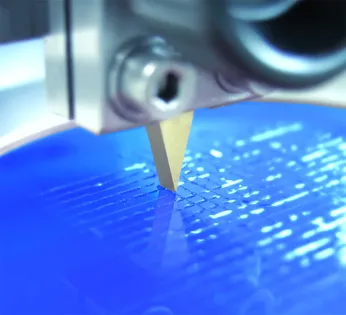

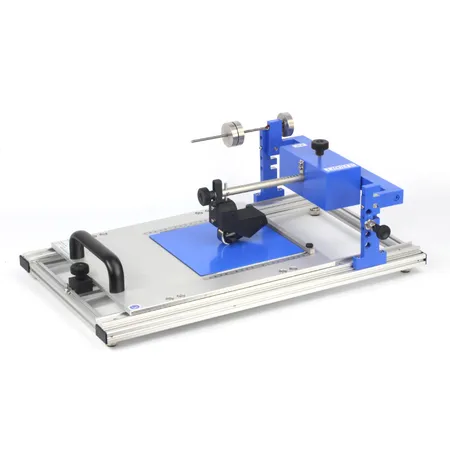

A widely used method for testing adhesive strength is the cross hatch cutting test, which can be performed manually (Model Series 295) or automatically (Model Series 430 P-Smart). In manual testing, the depth of the cuts into the substrate can vary depending on the applied force. Automatic testing devices (Models 430 P-Smart), on the other hand, operate with consistent force application, ensuring comparability and repeatability of the tests.

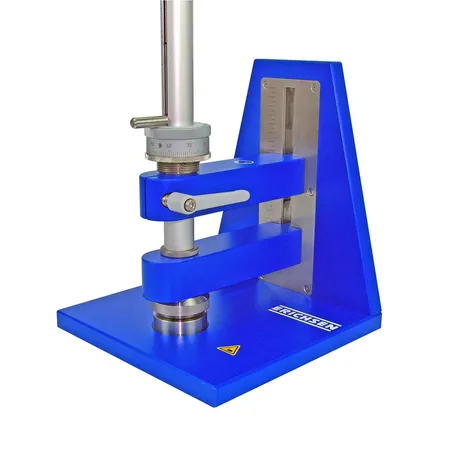

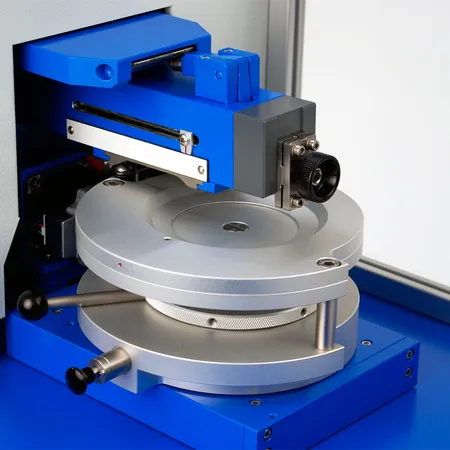

Pull-off Test

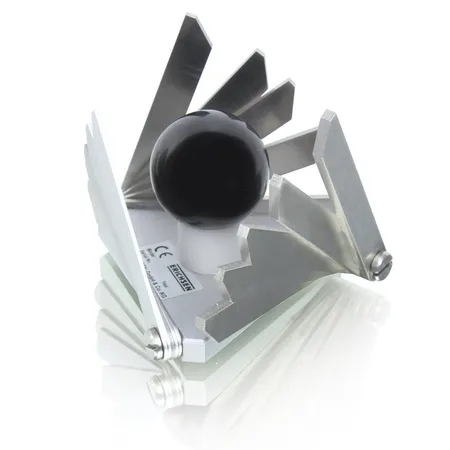

Another common method for testing adhesive strength is the pull-off test (Model Series 525). For coating materials, it is essential, at least as part of their protective function, to resist potentially damaging mechanical influences as effectively as necessary or possible. The term "impact resistance" refers to the effect of localized kinetic energy and its influence on the durability of the coating.

A coating material should ideally adapt to the deformations of the substrate without cracking or losing adhesion. Deformation can occur as part of a deliberate, desired shaping process – either manual or mechanical – or as a result of temperature-induced expansion or contraction. In all these cases, an appropriately tailored elastic property of the coating material, its elasticity, ideally ensures consistent and sufficiently strong adhesion to the substrate, regardless of shape, within certain limits.