Bulge-/FLC-Tester Model 161

Videos

By clicking on the following button, you agree that videos may be loaded from YouTube. You can find information on this in our privacy policy.

Link

Description

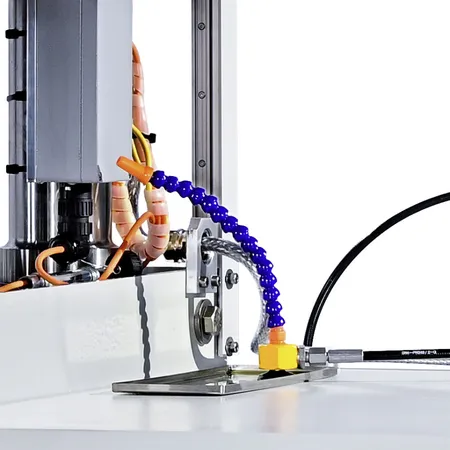

The Model 161 Bulge/FLC tester is an electro-hydraulic testing machine that is used to carry out hydraulic cupping tests on all ferrous and non-ferrous metals. Samples up to 400 x 650 mm in size can be tested. In addition to the actual hydraulic forming, its construction also enables it to be used with ball stamps (FLC) of any diameter from 100 to 199 mm.

The hydraulic cylinder, the hydraulic aggregate as well as the control devices are housed within the body of the machine.

The four-column frame with integrated test tool, allows the test of specimens up to a size of 400 x 650 mm.

The Bulge-/FLC Tester, Model 161, with programmable logic controller (PLC) is provided with a maximum drawing force (bulge force) of 1,000 kN . The bulge diameter is max. 200 mm. The control of the maximum drawing speed is effected via a proportional distribution valve with pressure balance. The blank holder force of max. 1,000 kN is infinitely variable and is controlled by a proportional pressure regulating valve. The clamping stroke is 180 mm.

The Bulge-/FLC Tester, Model 161, is equipped with analogue outputs for data acquisition when using an own evaluation systems. The captured data of drawing force and blank holder force can be processed in this way by a separate evaluation unit.

For safety reasons the test area of the Bulge-/FLC Tester, Model 161, is provided with high-rigidity, transparent protective lids. The Testing Machine can only be started, when all protective lids are closed and thus it is no longer possible to reach into the tool area.

Purpose and Application

The operation of the Bulge/FLC Tester, Model 161, is most simple. After the specimen has been placed into the test head, the hydraulic system is started with the help of a push button whereupon in the first instance the test panel is clamped tightly. Thereafter the drawing piston moves upwards and presses the quantity of oil that is located between the piston and the test panel, into the direction of the test panel so that the specimen is formed into a spherical bulge.

The automatic crack detection can be activated by using the “crack" switch.

At specimen failure the drawing piston is stopped by way of the crack detection automatism and returns into its starting position. Since the crack detection automatism acts on a retrograde signal, it is possible that the sheet metal panel tested does not yet show a fracture, especially in the case of thick material. With the help of a time lag relay the switching-off can be delayed until the fracture occurs.

The acquisition and evaluation of the measuring points on the bulge surface can be carried out by optical evaluation systems like "Aramis" from GOM or "Auto Grid" from VIALUX.

Scope of delivery

- Bulge-/FLC-Tester, Model 161

- Operating instructions