Selection Guide – Standard Compliance for Corrosion Testing Devices

Our overview "Standard Compliance for Corrosion Testing Devices" shows which ERICHSEN corrosion testing devices meet the requirements of the respective standards – for an easy and secure selection.

Corrosion Resistance on the test bench

Eventually, almost every material will be affected by corrosion. There are only a few materials, such as precious metals, that can withstand corrosion for a long time. Acid rain, exhaust gases, and other influences of civilization accelerate the degradation of value.

Thanks to ERICHSEN's advanced corrosion testing devices, the effects of salt fog and condensation water can be examined and reliably determined according to various norms and standards.

Precise corrosion tests according to international standards

ERICHSEN offers testing equipment for salt spray tests (ASTM B117, ISO 9227, etc.), alternating corrosion tests (PV 1210, VDA 233-102, etc.), condensation tests (DIN EN ISO 6270-2, etc.) and many other corrosion tests in accordance with all common norms and standards.

Humidity Chambers

Using the ERICHSEN humidity cabinets and humdity chambers it is possible to make corrosion caused by condensation water climate measurable. The condensation water test is the basis for the determination of surface corrosion.

Erichsen humidity chambers are designed for standard-compliant individual and mass tests of small and large-volume functional parts according to, for example, DIN EN ISO 6270-2. With our humidity cabinet Model 519 Smart, "Kesternich tests" with SO2 harmful gas can also be carried out.

More information

Corrosion Testing Equipment

Thanks to ERICHSEN's highly developed corrosion testing equipment, the effects of salt spray and condensation water can be examined and reliably determined in accordance with a wide range of norms and standards.

ERICHSEN offers test equipment for salt spray tests (ASTM B117, ISO 9227, etc.), corrosion change tests (PV 1210, VDA 233-102, etc.), condensation water tests (DIN EN ISO 6270-2, etc.) and many other corrosion tests according to all common norms and standards.

More information

Weathering Tester

The aggressive influences of moisture, acids, alkalis and gases have a particularly corrosive effect on metals. Corrosion in plastics occurs, among other things, through the dissolution of plasticisers. UV light, heat and the absorption of foreign substances accelerate this development. Plastics do not rust, but the corrosion becomes noticeable by cracking, softening, embrittlement and colour change.

More information

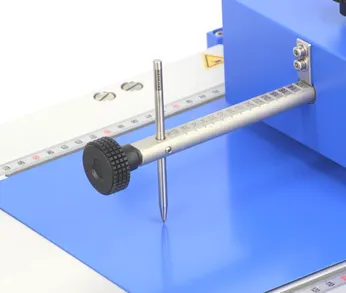

Sample preparation

It is a common procedure to prepare coated test sheets for corrosion tests by applying various linear scoring marks in vertical, horizontal and intersecting forms in order to test the resistance of the coating system to sub-corrosion. For this purpose, in addition to the use of a test probe according to "van Laar" as a scribing tool, a test probe according to "Clemen" is often prescribed as a scribing tool. A single test probe for cross-cut tests is also occasionally used.

More information